A hydroelectric power station is an electricity generation facility that harnesses the energy of flowing water to produce electrical power. It converts the gravitational potential energy of water into kinetic energy and then transforms this kinetic energy into electricity. Here is the basic principle of how a hydroelectric power station generates electricity:

1. Water Reservoir Regulation

1.1 Water Resource Management

Hydroelectric power stations are typically built upstream of rivers, utilizing reservoirs to store large amounts of water. This design not only ensures effective use of water resources but also provides flexible scheduling capabilities. During peak electricity demand, the reservoir can release a significant amount of water for the turbines, while during low demand periods, water flow can be restricted to conserve resources. This dynamic management helps balance electricity supply and demand, enhancing the reliability and operational efficiency of the system.

1.2 Water Level Control

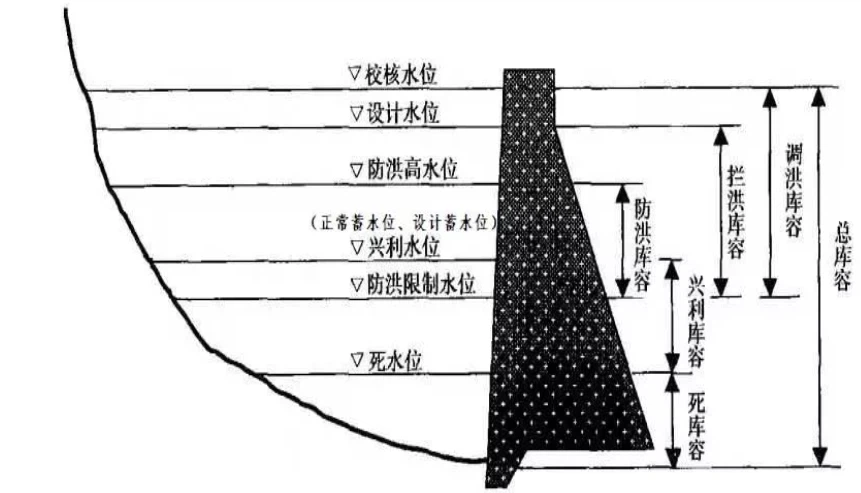

The water level in the reservoir can be precisely controlled through gates and spillways. This capability is crucial because changes in water level directly affect the operational efficiency of the turbines and their power generation capacity. A low water level may lead to reduced power generation, while a high water level could result in overflow and safety risks. Therefore, reservoir management systems are typically equipped with sensors and control systems to monitor water levels in real-time and respond quickly.

1.3 Environmental Protection

The construction and management of reservoirs must also consider their environmental impact. Large-scale reservoirs can disrupt local ecosystems, so environmental impact assessments are often conducted during the planning of hydroelectric projects. This includes protecting aquatic habitats, monitoring water quality in the watershed, and analyzing the socio-economic impacts on surrounding communities. Modern hydroelectric stations increasingly emphasize sustainable development, seeking to balance power generation with environmental protection.

2. Turbine

2.1 Types of Turbines

The turbine is a key component of a hydroelectric power station, primarily converting the kinetic energy of water flow into mechanical energy. There are various types of turbines, with the most common being impulse turbines and reaction turbines. Impulse turbines are typically suited for high head and low flow conditions, while reaction turbines perform well in low head and high flow applications. Selecting the appropriate turbine type is crucial for maximizing power generation efficiency.

2.2 Mechanical Design

The design of the turbine blades is also critical. The shape, material, and angle of the blades affect the hydrodynamic characteristics of the water flow and the overall efficiency of the turbine. Modern turbines often utilize advanced computational fluid dynamics (CFD) techniques for design and optimization to ensure optimal energy conversion under various operating conditions. Additionally, regular maintenance and inspections can extend the turbine's lifespan and enhance power generation efficiency.

2.3 Safety and Redundancy Design

Turbines must withstand significant water pressure and mechanical stress during operation, necessitating high safety standards. Modern hydroelectric station designs often incorporate redundant systems to ensure safe operation in the event of equipment failure. These measures not only protect the integrity of the equipment but also ensure the stability of the power generation process, ultimately improving the reliability of the entire power system.

3. Generator

3.1 Generator Principles

The primary function of the generator is to convert the mechanical energy produced by the turbine into electrical energy. This is achieved through the principle of electromagnetic induction. As the turbine rotates, the rotor inside the generator also spins, causing the conductive coils to move within a magnetic field, thereby generating electric current. Generators can be classified into synchronous and asynchronous types, each with unique operational characteristics and applications.

3.2 Design and Efficiency

Modern generators are designed for high efficiency, utilizing high-quality materials to maximize conversion efficiency. The configuration of the electromagnetic coils, the strength of the magnetic field, and the optimization of rotational speed all significantly impact generator efficiency. Many generators are also equipped with advanced monitoring and control systems to adjust operational states in real-time, ensuring the stability and reliability of the power output.

3.3 Maintenance and Inspection

Generators may experience wear or failure after prolonged operation, making regular maintenance and inspection essential. Maintenance tasks include checking, lubricating, and replacing various components. By following standardized maintenance procedures, the lifespan of the generator can be effectively extended, and overall power generation efficiency can be improved. Additionally, monitoring systems can provide real-time data to help technicians quickly identify issues and take appropriate action.

4. Transformer

4.1 Transformer Operating Principles

Transformers play a crucial role in regulating voltage within hydroelectric power stations. Their operation is based on electromagnetic induction. When alternating current flows through the input coil, it generates a magnetic field in the transformer core, which then influences the output coil, generating voltage. By adjusting the turns ratio between the input and output coils, transformers can increase or decrease voltage to meet different power transmission needs.

4.2 Efficient Design

Modern transformers utilize advanced design techniques to continuously improve energy efficiency and reduce energy losses. High-quality insulation materials, precise core designs, and optimized cooling systems are all critical factors in enhancing transformer efficiency. During the initial design phase, engineers consider operational environments, load variations, and frequency to ensure that the transformer functions properly over its lifespan.

4.3 Safety and Monitoring

Transformers generate heat and experience voltage fluctuations during operation, necessitating effective control measures. Modern transformers are equipped with various safety protection devices, such as overcurrent protection and temperature monitoring functions. These devices can quickly detect potential faults, ensuring the safe operation of the system. Additionally, real-time monitoring systems help maintenance personnel respond swiftly to anomalies, minimizing economic losses and safety incidents.

5. Transmission and Distribution

5.1 Transmission System Design

Electricity is transmitted from hydroelectric power stations through high-voltage transmission lines, requiring carefully designed transmission systems. Factors such as the selection of transmission lines, spacing of transmission towers, and routing of lines involve a comprehensive consideration of engineering technology and economic efficiency. High-voltage transmission effectively reduces energy losses during transport, which is why modern transmission systems typically adopt high voltage standards to enhance overall efficiency.

5.2 Transmission Networks and Smart Grids

In modern power systems, smart grid technology is widely applied. Smart grids can monitor the flow of electricity in real-time, achieving a high level of automation and scheduling. Therefore, when electricity demand fluctuates, the system can respond quickly to adjust power output. Additionally, the use of smart meters and monitoring devices allows users to understand their electricity consumption in real-time, optimizing usage patterns to reduce costs and improve energy efficiency.

5.3 Power Distribution at the User End

At the user end, transformers convert high-voltage electricity into low-voltage electricity suitable for residential and commercial use. The distribution system then allocates electricity to various consumers, including homes, businesses, and industrial enterprises. This process must ensure fairness and stability in power distribution to meet the diverse needs of different users. Modern distribution networks also consider the integration of renewable energy sources and peak load scheduling, promoting more flexible energy usage patterns.

Summary

Hydroelectric power stations convert the gravitational potential and kinetic energy of water into electrical energy through all these processes, forming a complete and efficient power generation system. Hydroelectric power generation is a renewable and environmentally friendly energy solution that helps reduce greenhouse gas emissions while providing stable electricity supply for modern society. With continuous technological advancements, the design and operation of hydroelectric stations will increasingly focus on environmental protection and sustainable resource utilization, contributing positively to the future of green energy development.

At the same time, we at HYDGET have many years of experience and achievements in the design and supply of hydraulic turbines and power stations. We sincerely welcome domestic and international customers to come and inquire.!!